Structural Insulated Panels (SIPs)

Structural Insulated Panels (SIPS) are at the core of the Siphaus Advanced Building System.

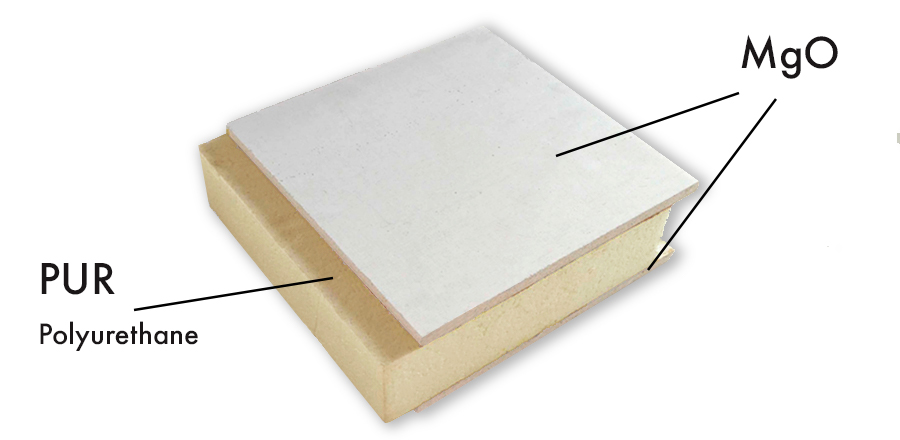

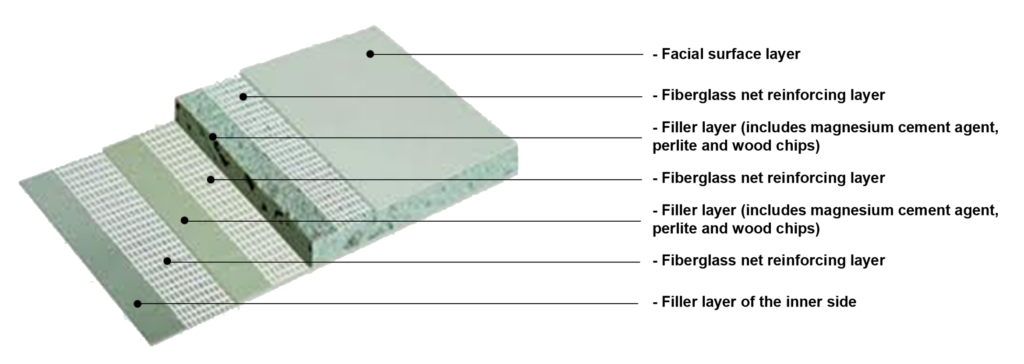

The outer structure of the Siphaus SIP panel system is Class A Grade Chloiride Free Magnesium Oxide, which is highly water resistant, fireproof and extremely strong. The thermal core comprises Elastapor® H PUR foam insulation, developed with world market leaders BASF.

Siphaus SIP panels are manufactured in a highly controlled factory environment, working to ISO 9001 standards, to produce one of the most advanced performance build systems available today.

SiphausSIP panels are the perfect solution for rapidly constructing thermally efficient, airtight buildings. Our panels can be used for external and internal walls, roofs and intermediate floors, in virtually any design and application. The panels are very easy to erect on site and typically allow the building envelope to be constructed to wind and watertight state within days of delivery to site.

SIP building advantages

Design

Construct virtually any style of building from the traditional to the contemporary. Each building supplied will have been structurally designed by our engineers. Standardised panel sizes and connection components allow for extreme ease and flexibility of configuration.

Thermal Efficiency

The excellent thermal performance of the Siphaus SIP panels combined with their ability to minimise thermal bridging and maximise thermal airtightness, means that high levels of performance can be easily achieved using our build system.

Finishes

Siphaus SIP panels allow for a wide range of finishes to be applied, including render, brick-slip, timber cladding, composite panel or even stone.

Ease of Construction

Siphaus panels are precision manufactured off-site, they go together quickly and accurately on-site. This means the finished building will adhere to the original dimensions planned, within a very tight tolerance. It is relatively simple to erect and requires no wet trades and has low wastage which allows for accurate fixed costs. External and internal follow on trades can start work sooner and the build system offers a weather tight shell helping you complete faster.

Time Saving and Safety

The Siphaus integrated build system dramatically reduces construction time and labour costs. The assembly of the building structure is typically measured in days rather than weeks or months. It is far easier to accurately predict completion times, reductions in on-site work, site deliveries, heavy materials and wastage all leading to improved site efficiency and safety.

Main advantages of the MgO boards

Non-combustible (rated A)

Impact-resistant

Breathable and porous for strong coating and adhesive bond

Refractory material for infrared radiation (heat) assisting to reduce loss of energy when heating or cooling by reducing conductivity

Excellent acoustic dampening material with higher density and elasticity

Silica/asbestos free

Freeze/Thaw-Tested for 36 months

Chemicaly inert

UV resistant

Mold/fungus/bug free (non-nutritious to mold, fungus, insects)

Non-hazardous, natural, non-toxic and disposable as crushable clean fill – Environmentally friendly

Main advantages of the PUR Core

PUR foam is a far better insulator and offers the best physical properties of any available insulating.

The BASF PUR foam has a stable R and U’- value per cm of thickness with a relatively thin MgO-SIP panel.

Safe and easy to use, PUR foam also has better fire, flame and smoke characteristics and will not melt.

It can withstand constant high service temperatures and will only char up to 450°C.

Unlike some blowing agents PUR foam is not a volatile organic compound(VOC) and, hence, does not contribute to ozone depletion (OD).

Additional benefits of Polyurethane include:

Helps avoid mold and mildew growth

Does not support nesting by vermin

Contains no formaldehyde

Aids in maintaining indoor comfort level

Reduces materials needed for construction of energy-efficient buildings

Reduces fuel consumption and infiltration of noise

Durable with excellent tensile strength and adhesion

Provides consistent performance for the service life of the structure

Panel caracteristics

- Dimensions: H X L = 2700 X 1200 mm

- Thicknesses: 100, 125, 150, 200, 250 mm

- Panel face board thickness T:= 12.5mm

- Core thickness C:= D – 2*T= 125mm

- MgO density ρ := 888.57 kg / m3

- PUR Core density ρ := 42.75 kg / m3

- Panel weight Wp = 31kg/m²

Custom corner pieces

- Up to 1200 x 1200 x 2700 mm

- Exact angles